PTC Facilities

Progressive Tools & Components Pvt. Ltd. is a renowned leader in precision tool designing and manufacturing. Leveraging industry-leading software including CATIA, Pro-E, and AutoCAD, we deliver innovative solutions that exceed the exacting standards of our clients. Our expertise in these advanced design tools allows us to achieve optimal performance and efficiency in every project.

With a focus on precision, our team utilizes the robust capabilities of CATIA to create intricate geometries and simulate real-world conditions. From conceptualization to detailed design, CATIA enables us to translate client requirements into high-precision solutions with unparalleled accuracy.

Similarly, Pro-E empowers us to tackle design challenges with agility and efficiency. Its parametric design environment enables rapid iterations and optimization for manufacturability, ensuring that our designs are both innovative and practical.

AutoCAD rounds out our suite of design software with its intuitive interface and powerful drafting capabilities. Whether creating 2D sketches or detailed technical drawings, AutoCAD allows us to communicate our design intent with clarity and precision, streamlining our design process and facilitating seamless collaboration.

At Progressive Tools & Components Pvt. Ltd., our integrated approach to design and manufacturing ensures that our products meet the highest standards of quality and reliability. From prototyping to production, we maintain rigorous quality control measures to ensure optimal performance and efficiency in every project.

Driven by innovation and a commitment to excellence, we strive to push the boundaries of what is possible in precision tool designing and manufacturing. With our expertise in industry-leading software and a dedication to meeting client expectations, we continue to set new standards of quality and reliability in the industry.

Cutting Machines

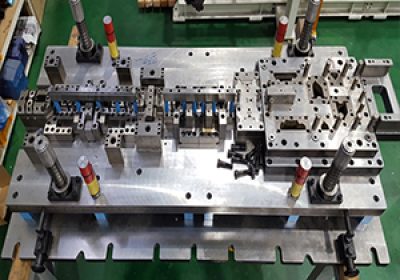

Progressive Tools & Components Pvt. Ltd. stands as a distinguished leader in the manufacturing landscape, equipped with a diverse range of cutting-edge capabilities that set us apart in the industry. Our arsenal includes CNC milling centers with bed sizes extending up to an impressive 2600mm x 4000mm, ensuring the capacity to handle projects of varying scales with precision and efficiency.

In addition to our CNC milling capabilities, we offer a host of other advanced manufacturing processes, including wire cutting, EDM (Electrical Discharge Machining), jig boring, optical profile cutting, and a multitude of conventional machines. This comprehensive array of machinery enables us to undertake a wide spectrum of projects, from intricate components to large-scale tooling, catering to the diverse needs of our clients across various industries.

At Progressive Tools & Components Pvt. Ltd., we take immense pride in our state-of-the-art equipment and facilities. Our investment in cutting-edge technology reflects our commitment to delivering superior quality and performance in every project we undertake. With meticulous attention to detail and a focus on precision engineering, we ensure that each component and tool we produce meets the highest standards of excellence.

Moreover, our team of skilled engineers, technicians, and craftsmen brings a wealth of experience and expertise to every project. Their dedication to innovation and continuous improvement drives our quest for excellence, enabling us to stay at the forefront of technological advancement and deliver innovative solutions that exceed client expectations.

Whether it’s precision-engineered components for the automotive industry, specialized tools for aerospace applications, or custom solutions for medical devices, Progressive Tools & Components Pvt. Ltd. is equipped to handle the most demanding projects with confidence and competence. Our commitment to quality, performance, and customer satisfaction is unwavering, making us the preferred partner for clients seeking reliable and efficient manufacturing solutions.

In conclusion, Progressive Tools & Components Pvt. Ltd. stands as a beacon of excellence in the manufacturing sector, offering a comprehensive array ofcapabilities backed by state-of-the-art equipment, expertise, and a relentless commitment to quality. With our precision-engineered components and tools, we enable our clients to achieve their goals with confidence, driving success and innovation across diverse industries.

Quality Testing & Preventive Machines

At Progressive Tools & Components Pvt. Ltd., our commitment to quality goes beyond the ordinary. We pride ourselves on our ability to deliver excellence through the integration of advanced technologies into our quality assurance processes. By leveraging cutting-edge instruments like the Hardness Tester, Faro Arm CMM, and other specialized equipment, we ensure that every component meets the highest standards of precision and reliability.

The Hardness Tester is a crucial tool in our arsenal, allowing us to assess the hardness and durability of materials with pinpoint accuracy. This enables us to verify the quality of our components and ensure that they possess the necessary strength and resilience to withstand the rigors of real-world applications. By subjecting our products to rigorous hardness testing, we can guarantee their performance and longevity, providing our clients with peace of mind and confidence in their investments.

In addition to the Hardness Tester, we utilize the Faro Arm CMM (Coordinate Measuring Machine) to conduct comprehensive dimensional inspections and validate the accuracy of our components. This advanced metrology tool utilizes precise laser scanning technology to capture detailed 3D measurements, enabling us to verify the conformity of our products to exacting specifications. With the Faro Arm CMM, we can detect even the smallest deviations and ensure that our components meet the tightest tolerances, thereby delivering the right product to our clients with unmatched precision.

Furthermore, we augment our quality assurance processes with a range of other specialized equipment, each tailored to specific aspects of component validation and inspection. From optical measurement systems to surface roughness testers, we employ an array of cutting-edge tools to address diverse quality requirements and ensure the integrity of our products at every stage of production.

At Progressive Tools & Components Pvt. Ltd., our investment in advanced quality instruments reflects our unwavering commitment to excellence and customer satisfaction. By harnessing the power of technology and innovation, we continuously strive to raise the bar in precision engineering and deliver superior products that exceed the expectations of our clients. With our comprehensive quality assurance processes and state-of-the-art equipment, we stand ready to meet the most demanding challenges and provide our clients with the right products they can rely on, every time.

Fabrication Facility

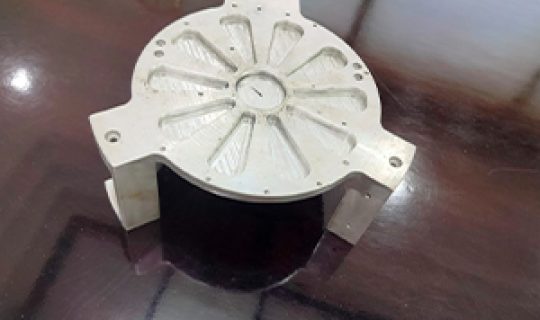

Progressive Tools & Components Pvt. Ltd. is a trusted leader in mechanical assemblies, welding fixtures, frames, and heavy fabrication services. With a focus on excellence and innovation, we offer a comprehensive range of solutions to meet the diverse needs of our clients. Our expertise spans across a wide spectrum of welding processes, including MIG, TIG, Arc, and Spot welding, allowing us to deliver high-quality and precision-engineered products.

One of our key strengths lies in our commitment to employee training and involvement. We believe that investing in our team is crucial to maintaining our competitive edge and delivering exceptional results. Through continuous training and development programs, we ensure that our employees are equipped with the latest skills and knowledge necessary to excel in their roles. This emphasis on employee involvement fosters a culture of collaboration, innovation, and continuous improvement, enabling us to consistently meet and exceed the expectations of our clients.

In addition to our welding capabilities, we offer comprehensive heavy fabrication services, including the fabrication of frames, structures, and components. Our state-of-the-art facilities and advanced equipment enable us to undertake projects of varying complexities with precision and efficiency. Whether it’s a small-scale component or a large structural assembly, our team is dedicated to delivering superior quality products that meet the highest standards of excellence.

To further enhance our manufacturing capabilities, we provide overhead cranes with a capacity of up to 10 tons for efficient material handling. These cranes enable us to streamline our production processes, optimize workflow efficiency, and ensure timely delivery of projects. By investing in advanced equipment and infrastructure, we demonstrate our commitment to providing our clients with the highest level of service and reliability.

At Progressive Tools & Components Pvt. Ltd., customer satisfaction is our top priority. We work closely with our clients to understand their unique requirements and tailor our solutions to meet their specific needs. Whether it’s a one-off project or a long-term partnership, we are dedicated to delivering excellence in every aspect of our business. With our extensive capabilities, experienced team, and unwavering commitment to quality, we are proud to be the preferred choice for mechanical assemblies, welding fixtures, frames, and heavy fabrication services

Our Esteemed Customer

Progressive Tools & Components Pvt. Ltd. stands as a trusted partner to a diverse clientele, catering to esteemed organizations such as Bharat Electronics Limited in Ghaziabad, Honda Car India Ltd., BHEL in Jhansi, Bhopal, and Ranikhet, as well as Metso Minerals (India) Pvt. Ltd. Our commitment to excellence, innovation, and precision engineering forms the cornerstone of our service offerings.

At Progressive Tools & Components Pvt. Ltd., we recognize that each client has unique requirements and challenges. Therefore, we approach every project with a tailored mindset, ensuring that our solutions are perfectly aligned with the specific needs of our clients. Whether it’s designing precision components for Bharat Electronics Limited’s advanced electronic systems, supplying high-quality parts for Honda Car India Ltd.’s vehicles, or providing heavy fabrication services for BHEL’s power projects in Jhansi, Bhopal, and Ranikhet, we go above and beyond to deliver superior results.

Our partnership with Metso Minerals (India) Pvt. Ltd. further demonstrates our expertise in providing specialized solutions for the mining and aggregates industry. From designing custom components to delivering heavy-duty fabrication services, we leverage our technical capabilities and industry knowledge to support Metso Minerals in achieving their operational objectives.

At the heart of our success lies a relentless commitment to innovation and precision engineering. We invest in advanced technologies, state-of-the-art equipment, and continuous training for our team to ensure that we stay at the forefront of the industry and deliver cutting-edge solutions to our clients. By combining technical expertise with a customer-centric approach, we strive to exceed expectations and forge long-lasting partnerships built on trust and mutual success.

In conclusion, Progressive Tools & Components Pvt. Ltd. takes pride in serving a diverse clientele of industry leaders across various sectors. With our unwavering commitment to excellence, innovation, and precision engineering, we deliver tailored solutions that address the unique needs of each of our esteemed clients. Our dedication to quality and customer satisfaction remains unwavering as we continue to push the boundaries of what is possible in the manufacturing industry.